control panel vs junction box Local Control Panels (LCPs) are typically used to monitor, control and protect instrumentation systems. We offer LCPs that are easy to maintain and can be directly mounted on frames or skids. At CSE Solutions, our engineers have . It is good to use 0.023- or 0.025-inch diameter filler wire with MIG welding. As a rule of thumb, use a wire diameter that is thinner than the base metal. Typical welding parameters for MIG welding using 0.025 inches (0.6 .

0 · when to use junction box

1 · waterproof electrical distribution panel box

2 · junction box wall mounted

3 · junction box outlet

4 · junction box catalogue pdf

5 · junction box 200x150x100

6 · heavy duty junction box

7 · electrical panel junction box

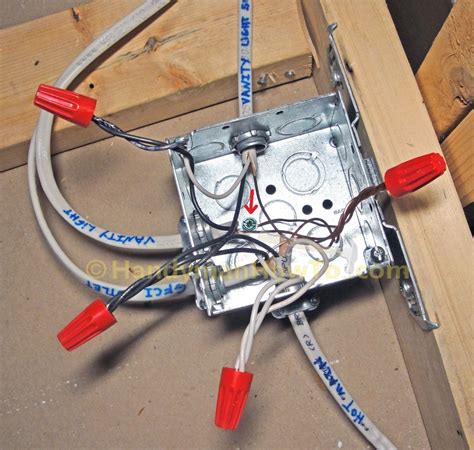

No, your existing outlets do not need to be grounded on a grandfathered 1950s home. Yes, GFCI is an alternative for many applications (e.g. kitchen, bathroom, other "wet" areas).

These junction boxes serve as a splice point to allow for larger multi-pair or multi-conductor (home run) cables to connect back to the central control system cabinet which held the.

The NEC allows you to use the control panel as a junction box for other wiring or systems [409.104(A)], if you provide ample space for this .Local Control Panels (LCPs) are typically used to monitor, control and protect instrumentation systems. We offer LCPs that are easy to maintain and can be directly mounted on frames or skids. At CSE Solutions, our engineers have .

The major difference between a junction box and a utility box is that a junction box would house the electrical connections while the utility boxes are used to install switches, .In simple terms, Marshalling cabinets are located between junction boxes and control system. Within the marshalling cabinets, field cables are connected and cross-wiring is performed to order the signals according to the I/O modules.

In this article, we will learn more about a marshalling cabinet, review a typical layout, and compare it versus a junction box. In industrial applications, a marshalling cabinet provides . In this article, you’ll find a rundown of the different types of PLC Cabinets, tips on layout and wiring, and an exploration of the key components within these cabinets. We’ll also share insights from real-world case studies to . These junction boxes serve as a splice point to allow for larger multi-pair or multi-conductor (home run) cables to connect back to the central control system cabinet which held the.PLC Connection between field Instruments, Junction Box, Marshalling cabinet, System Cabinet and Human-Machine Interface. Study PLC Operation & PLC Wiring.

The NEC allows you to use the control panel as a junction box for other wiring or systems [409.104(A)], if you provide ample space for this purpose. However, such a design sacrifices modularity, complicating maintenance and .

Local Control Panels (LCPs) are typically used to monitor, control and protect instrumentation systems. We offer LCPs that are easy to maintain and can be directly mounted on frames or skids. At CSE Solutions, our engineers have extensive experience in developing and designing local control panels. The major difference between a junction box and a utility box is that a junction box would house the electrical connections while the utility boxes are used to install switches, fixtures, etc. Some useful information about Junction boxesIn simple terms, Marshalling cabinets are located between junction boxes and control system. Within the marshalling cabinets, field cables are connected and cross-wiring is performed to order the signals according to the I/O modules.

In this article, we will learn more about a marshalling cabinet, review a typical layout, and compare it versus a junction box. In industrial applications, a marshalling cabinet provides an interface between a control system (DCS/PLC) and the field instruments.

In this article, you’ll find a rundown of the different types of PLC Cabinets, tips on layout and wiring, and an exploration of the key components within these cabinets. We’ll also share insights from real-world case studies to help you make informed decisions. As discussed in the Typical Instrumentation Architecture and Automation System, the automation architecture of the plant has a marshalling cabinet between the junction box and the system cabinet.An instrument junction box is an enclosure housing terminals that allows interconnection between field devices (i.e. instruments, switches etc) in the process/production areas, and control or monitoring equipment typically located in the control room. These junction boxes serve as a splice point to allow for larger multi-pair or multi-conductor (home run) cables to connect back to the central control system cabinet which held the.

PLC Connection between field Instruments, Junction Box, Marshalling cabinet, System Cabinet and Human-Machine Interface. Study PLC Operation & PLC Wiring. The NEC allows you to use the control panel as a junction box for other wiring or systems [409.104(A)], if you provide ample space for this purpose. However, such a design sacrifices modularity, complicating maintenance and .Local Control Panels (LCPs) are typically used to monitor, control and protect instrumentation systems. We offer LCPs that are easy to maintain and can be directly mounted on frames or skids. At CSE Solutions, our engineers have extensive experience in developing and designing local control panels.

ericson electrical boxes

The major difference between a junction box and a utility box is that a junction box would house the electrical connections while the utility boxes are used to install switches, fixtures, etc. Some useful information about Junction boxesIn simple terms, Marshalling cabinets are located between junction boxes and control system. Within the marshalling cabinets, field cables are connected and cross-wiring is performed to order the signals according to the I/O modules. In this article, we will learn more about a marshalling cabinet, review a typical layout, and compare it versus a junction box. In industrial applications, a marshalling cabinet provides an interface between a control system (DCS/PLC) and the field instruments. In this article, you’ll find a rundown of the different types of PLC Cabinets, tips on layout and wiring, and an exploration of the key components within these cabinets. We’ll also share insights from real-world case studies to help you make informed decisions.

As discussed in the Typical Instrumentation Architecture and Automation System, the automation architecture of the plant has a marshalling cabinet between the junction box and the system cabinet.

when to use junction box

Get the best deals for western electric 755a at eBay.com. We have a great online selection at the lowest prices with Fast & Free shipping on many items!

control panel vs junction box|waterproof electrical distribution panel box