solidworks sheet metal rip Rips. A rip feature is commonly used to create sheet metal parts, but you can . how to wire a 240 volt 20 amp junction box and what to do with the white wire consult with codes before doing electrical work

0 · solidworks sheet metal rip feature

1 · solidworks sheet metal

2 · solidworks rips tool

3 · solidworks rip template

4 · solidworks rip schematic

5 · solidworks rip properties

6 · solidworks rip parameters

7 · solidworks rip feature

A junction box that is 4-by-4 inches with a 1-1/2-inch depth can hold up to 10 14-gauge or 9 12-gauge wires. What are the wires in a junction box? Junction boxes contain hot (black), neutral (white), and grounding (green or copper) wires.

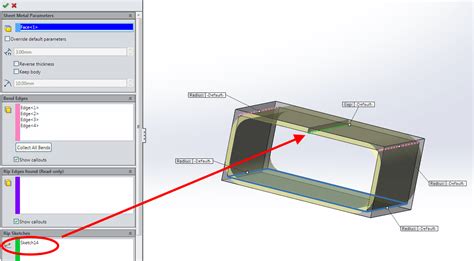

Click Rip (Sheet Metal toolbar) or Insert > Sheet Metal > Rip. In the PropertyManager, under Rip Parameters: Select internal or external edges. Select linear sketch entities.You can use the Rip tool to create rips in hollow or thin-walled cylindrical and .A rip feature is commonly used to create sheet metal parts, but you can add a rip .To use a rip sketch when converting to sheet metal: Open the part. Click .

Rips. A rip feature is commonly used to create sheet metal parts, but you can .Rips. A rip feature is commonly used to create sheet metal parts, but you can add a rip feature to any part. You can create a rip feature: Along selected internal or external model edges. From linear sketch entities. By combining model edges .

Learn how to convert a regular solid into a sheet metal part using the rip feature in SOLIDWORKS. Explore our library of SOLIDWORKS tutorials today: https://. Want all of our free SolidWorks - Sheet Metal training videos? Visit our Learning Library, which features all of our training courses and tutorials at http:/. How to use the rip and insert bends feature in Solidworks Sheet Metal.

You can use the Rip tool to create rips in hollow or thin-walled cylindrical and conical bodies. By selecting an edge on a cylindrical or conical face, you can flatten the part as sheet metal. Rip . SOLIDWORKS Sheet Metal Rip options can be applied according to design intent and manufacturing requirements, here are examples of the different options.

A rip feature is commonly used to create sheet metal parts, but you can add a rip feature to any part. To create a rip In this video we are going to learn about the uses of Rip command in solidworks sheet metal.To use a rip sketch when converting to sheet metal: Open the part. Click Convert to Sheet Metal (Sheet Metal toolbar) or Insert > Sheet Metal > Convert To Sheet Metal . In the .

To use the rip tool in a cylindrical part: In a hollow or thin-walled cylindrical or conical part, click Rip (Sheet Metal toolbar). In the graphics area, select: An edge. A reference point on the model. The reference point can be on the model or .To use the rip tool in a cylindrical part: In a hollow or thin-walled cylindrical or conical part, click Rip (Sheet Metal toolbar). In the graphics area, select: An edge. A reference point on the model. The reference point can be on the model or anywhere in the graphics area.A rip feature is commonly used to create sheet metal parts, but you can add a rip feature to any part. Parent topicUsing Sheet Metal Tools. Creating a Sheet Metal Part Using Round Bends. . Version: SOLIDWORKS 2021 SP05 To disable .

In this video we are going to learn about the uses of Rip command in solidworks sheet metal.Click Insert Bends (Sheet Metal toolbar) or Insert > Sheet Metal > Bends.; In the PropertyManager, under Bend Parameters:. Click a face or edge on the model for Fixed Face or Edge.The fixed face remains in place when the part is flattened. Set a value for Bend Radius.; Under Bend Allowance, select from: Bend Table, K-Factor, Bend Allowance, Bend Deduction, .For sheet metal parts created in SOLIDWORKS . You can convert any imported sheet metal type part to a SOLIDWORKS sheet metal part. Using Rip Sketches with Convert to Sheet Metal. When a rip is required to create a sheet metal part, you can use 2D and 3D sketches to define the rip. You must create the sketch before converting the solid body to .A rip feature is commonly used to create sheet metal parts, but you can add a rip feature to any part. You can create a rip feature: Along selected internal or external model edges; . EXPERIENCE SOLIDWORKS) 2025 SP0 To disable help from within SOLIDWORKS and use local help instead, click Help > Use SOLIDWORKS Help.

When a rip is required to create a sheet metal part, you can use 2D and 3D sketches to define the rip. You must create the sketch before converting the solid body to a sheet metal part. . SOLIDWORKS welcomes your feedback concerning the presentation, accuracy, and thoroughness of the documentation. .

In a part, click Rip (Sheet Metal toolbar) or Insert > Sheet Metal > Rip. Selections. Edges to Rip: Specifies internal or external edges, or linear sketch entities to rip. . Version: SOLIDWORKS 2024 SP05 To disable help from within SOLIDWORKS and use local help instead, click Help > Use SOLIDWORKS Help.With the Unfold and Fold tools, you can flatten and bend one, more than one, or all of the bends in a sheet metal part. Rips. A rip feature is commonly used to create sheet metal parts, but you can add a rip feature to any part. . SOLIDWORKS welcomes your feedback concerning the presentation, accuracy, and thoroughness of the documentation. .

For sheet metal parts created in SOLIDWORKS . You can convert any imported sheet metal type part to a SOLIDWORKS sheet metal part. Using Rip Sketches with Convert to Sheet Metal. When a rip is required to create a sheet metal part, you can use 2D and 3D sketches to define the rip. You must create the sketch before converting the solid body to .With the Unfold and Fold tools, you can flatten and bend one, more than one, or all of the bends in a sheet metal part. Rips. A rip feature is commonly used to create sheet metal parts, but you can add a rip feature to any part. . SOLIDWORKS welcomes your feedback concerning the presentation, accuracy, and thoroughness of the documentation. .Click Rip (Sheet Metal toolbar) or Insert > Sheet Metal > Rip. In the graphics area, select: Internal or external edges; Linear sketch entities; . SOLIDWORKS welcomes your feedback concerning the presentation, accuracy, and thoroughness of the documentation. Use the form below to send your comments and suggestions about this topic directly to .

solidworks sheet metal rip feature

When a rip is required to create a sheet metal part, you can use 2D and 3D sketches to define the rip. You must create the sketch before converting the solid body to a sheet metal part. . SOLIDWORKS welcomes your feedback concerning the presentation, accuracy, and thoroughness of the documentation. .Hi all, I haven't used sheet metal features extensively in Solidworks, so I am trying to create a simple version of a more complicated box that I am reverse engineering. . In the model views you can see the sketches I have used to rip the sheet. I've tried several other sketch configurations, but this one came to closest to getting what I .When a rip is required to create a sheet metal part, you can use 2D and 3D sketches to define the rip. You must create the sketch before converting the solid body to a sheet metal part. . SOLIDWORKS welcomes your feedback concerning the presentation, accuracy, and thoroughness of the documentation. .

Using Rip Sketches with Convert to Sheet Metal : Convert To Sheet Metal PropertyManager: . The sheet metal parameters (material thickness, bend radius, and bend calculation method) use the values stored in the gauge table unless you override them. . SOLIDWORKS welcomes your feedback concerning the presentation, accuracy, and thoroughness of .

Using Rip Sketches with Convert to Sheet Metal : Convert To Sheet Metal PropertyManager: . The sheet metal parameters (material thickness, bend radius, and bend calculation method) use the values stored in the gauge table unless you override them. . SOLIDWORKS welcomes your feedback concerning the presentation, accuracy, and thoroughness of .For sheet metal parts created in SOLIDWORKS . You can convert any imported sheet metal type part to a SOLIDWORKS sheet metal part. Using Rip Sketches with Convert to Sheet Metal. When a rip is required to create a sheet metal part, you can use 2D and 3D sketches to define the rip. You must create the sketch before converting the solid body to .Contents. Rip Tool. You can use the Rip tool to create rips in hollow or thin-walled cylindrical and conical bodies. By selecting an edge on a cylindrical or conical face, you can flatten the part as sheet metal. Slot PropagationClick Rip (Sheet Metal toolbar) or Insert > Sheet Metal > Rip. In the PropertyManager, under Rip Parameters: Select internal or external edges; Select linear sketch entities; . SOLIDWORKS welcomes your feedback concerning the presentation, accuracy, and thoroughness of the documentation. Use the form below to send your comments and .

Using Rip Sketches with Convert to Sheet Metal : Convert To Sheet Metal PropertyManager: . The sheet metal parameters (material thickness, bend radius, and bend calculation method) use the values stored in the gauge table unless you override them. . SOLIDWORKS welcomes your feedback concerning the presentation, accuracy, and thoroughness of .When a rip is required to create a sheet metal part, you can use 2D and 3D sketches to define the rip. You must create the sketch before converting the solid body to a sheet metal part. . SOLIDWORKS welcomes your feedback concerning the presentation, accuracy, and thoroughness of the documentation. . how to create rip insert bend and no bend command in solidworks,Using Rip Sketches with Convert to Sheet Metal : Convert To Sheet Metal PropertyManager: . The sheet metal parameters (material thickness, bend radius, and bend calculation method) use the values stored in the gauge table unless you override them. . SOLIDWORKS welcomes your feedback concerning the presentation, accuracy, and thoroughness of .

Using Rip Sketches with Convert to Sheet Metal : Convert To Sheet Metal PropertyManager: . The sheet metal parameters (material thickness, bend radius, and bend calculation method) use the values stored in the gauge table unless you override them. . SOLIDWORKS welcomes your feedback concerning the presentation, accuracy, and thoroughness of .To use the rip tool in a cylindrical part: In a hollow or thin-walled cylindrical or conical part, click Rip (Sheet Metal toolbar). In the graphics area, select: An edge. A reference point on the model. The reference point can be on the model or anywhere in the graphics area.

instrument junction box specification

installing metal roofing this old house

Lighting circuits using junction boxes. An alternative method, this uses the same wiring principles as the looped ceiling roses, but here the connections are made in junction boxes rather than the ceiling rose. The junction box effectively .

solidworks sheet metal rip|solidworks rip parameters