autodesk inventor sheet metal thickness Create a sheet metal part using the sheet metal template. The template uses your . CNC (Computer Numerical Control) machining is the process of using a machine to automatically remove material from raw stock based on a set of computer-generated instructions. It can be performed on almost any material from expanded polyurethane foam to .

0 · sheet metal inventor tutorial pdf

1 · inventor unfold sheet metal

2 · inventor sheet metal exercises pdf

3 · inventor sheet metal drawing

4 · inventor fold sheet metal

5 · edit sheet metal rule inventor

6 · convert to sheet metal inventor

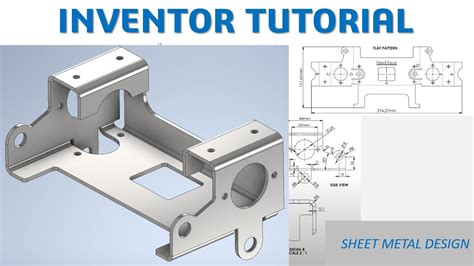

7 · Autodesk Inventor sheet metal tutorial

A junction box is a standard electrical box that encloses wire splices and contains no device (like a receptacle). What is a Type 1 junction box vs. a Type 2 junction box? The type 2 junction box is only for indoor use.

robert kaufman kaufman imperial collection metallic plum fabric

Typically, I would go into Tools\Parameters\Sheet Metal Paramaters and click on the "Thickness" row, and under the "Equation" column, and highlight the number and change it. In this instance, I can't highlight the number or change it.go to the sheet metal tab, under setup, pick sheet metal defaults, uncheck use .

Use the following steps: Define sheet metal template with custom iProperty - .Create a sheet metal part using the sheet metal template. The template uses your .Use the Sheet Metal Defaults dialog box to change the options and parameters .On the ribbon, click Sheet Metal tab Setup panel Sheet Metal Defaults. Optionally, .

rodanthe metallic outdoor fabric

go to the sheet metal tab, under setup, pick sheet metal defaults, uncheck use thickness from rule, type in the new value. Use the following steps: Define sheet metal template with custom iProperty - Thickness: Open empty sheet metal template. Open Parameters window (Manage Tab -> Parameters). Under Sheet Metal Parameters should .Create a sheet metal part using the sheet metal template. The template uses your settings for material thickness, bend radius, and corner relief. You use sketch commands to create a .Use the Sheet Metal Defaults dialog box to change the options and parameters defined by the selected Sheet Metal Rule for the active model state or to assign a unique thickness to a body .

This tutorial will show you how to create a thick or thin metal plate using the Inventor Sheet Metal tool.#inventor #howto #mufasucadOn the ribbon, click Sheet Metal tab Setup panel Sheet Metal Defaults. Optionally, override the Material, Thickness, or Unfolding Rule. If needed, change the sizes of the origin work planes to .

Edit Sheet Metal Thickness / Autodesk Inventor 2020https://youtu.be/0s6ecOLBf5MSimulate Spring Animationhttps://youtu.be/SaLr2C-M3yAMaking Pinion Gears Motio.To set the parameters, click Sheet Metal > Setup > Sheet Metal Defaults on the ribbon; the Sheet Metal Defaults dialog appears. This dialog displays the default preferences of the sheet metal .dialog, select the ‘Metric’ folder and choose ‘Sheet Metal (mm). ipt’ as the template. In the ribbon, select ‘Sheet Metal Defaults’. In the dialog, uncheck ‘Use Thickness from Rule’ and enter . Typically, I would go into Tools\Parameters\Sheet Metal Paramaters and click on the "Thickness" row, and under the "Equation" column, and highlight the number and change it. In this instance, I can't highlight the number or change it.

go to the sheet metal tab, under setup, pick sheet metal defaults, uncheck use thickness from rule, type in the new value. Use the following steps: Define sheet metal template with custom iProperty - Thickness: Open empty sheet metal template. Open Parameters window (Manage Tab -> Parameters). Under Sheet Metal Parameters should be parameter: "Thickness"

Create a sheet metal part using the sheet metal template. The template uses your settings for material thickness, bend radius, and corner relief. You use sketch commands to create a profile for a base face or an initial contour flange.

Use the Sheet Metal Defaults dialog box to change the options and parameters defined by the selected Sheet Metal Rule for the active model state or to assign a unique thickness to a body in a multibody part.This tutorial will show you how to create a thick or thin metal plate using the Inventor Sheet Metal tool.#inventor #howto #mufasucadOn the ribbon, click Sheet Metal tab Setup panel Sheet Metal Defaults. Optionally, override the Material, Thickness, or Unfolding Rule. If needed, change the sizes of the origin work planes to accommodate the average sheet metal size. Click File iProperties to . Edit Sheet Metal Thickness / Autodesk Inventor 2020https://youtu.be/0s6ecOLBf5MSimulate Spring Animationhttps://youtu.be/SaLr2C-M3yAMaking Pinion Gears Motio.

To set the parameters, click Sheet Metal > Setup > Sheet Metal Defaults on the ribbon; the Sheet Metal Defaults dialog appears. This dialog displays the default preferences of the sheet metal part such as sheet metal rule, thickness, material, and unfold rule. You can change these preferences as per your requirement. 2.dialog, select the ‘Metric’ folder and choose ‘Sheet Metal (mm). ipt’ as the template. In the ribbon, select ‘Sheet Metal Defaults’. In the dialog, uncheck ‘Use Thickness from Rule’ and enter 1.17mm as the thickness value. Change the material to ‘Stainless Steel.’ Select ‘OK’ to . Typically, I would go into Tools\Parameters\Sheet Metal Paramaters and click on the "Thickness" row, and under the "Equation" column, and highlight the number and change it. In this instance, I can't highlight the number or change it.

go to the sheet metal tab, under setup, pick sheet metal defaults, uncheck use thickness from rule, type in the new value. Use the following steps: Define sheet metal template with custom iProperty - Thickness: Open empty sheet metal template. Open Parameters window (Manage Tab -> Parameters). Under Sheet Metal Parameters should be parameter: "Thickness"

Create a sheet metal part using the sheet metal template. The template uses your settings for material thickness, bend radius, and corner relief. You use sketch commands to create a profile for a base face or an initial contour flange.Use the Sheet Metal Defaults dialog box to change the options and parameters defined by the selected Sheet Metal Rule for the active model state or to assign a unique thickness to a body in a multibody part.This tutorial will show you how to create a thick or thin metal plate using the Inventor Sheet Metal tool.#inventor #howto #mufasucad

On the ribbon, click Sheet Metal tab Setup panel Sheet Metal Defaults. Optionally, override the Material, Thickness, or Unfolding Rule. If needed, change the sizes of the origin work planes to accommodate the average sheet metal size. Click File iProperties to . Edit Sheet Metal Thickness / Autodesk Inventor 2020https://youtu.be/0s6ecOLBf5MSimulate Spring Animationhttps://youtu.be/SaLr2C-M3yAMaking Pinion Gears Motio.

sheet metal inventor tutorial pdf

To set the parameters, click Sheet Metal > Setup > Sheet Metal Defaults on the ribbon; the Sheet Metal Defaults dialog appears. This dialog displays the default preferences of the sheet metal part such as sheet metal rule, thickness, material, and unfold rule. You can change these preferences as per your requirement. 2.

inventor unfold sheet metal

inventor sheet metal exercises pdf

Air bending involves pressing sheet metal against a die to achieve a desired angle. However, the sheet metal never makes complete contact with the die. Air bending is Ameritex’s go-to method for precision sheet metal forming. It’s ideal for creating 90-degree bends commonly found in applications such as enclosures and brackets.

autodesk inventor sheet metal thickness|sheet metal inventor tutorial pdf