design of sheet metal brackets When it comes to sheet-metal brackets, there are several standard styles and shapes. Each sheet metal bracket style serves a specific requirement for mounting a component, or being compatible with a particular surface shape. Learn about the wiring diagram for a junction box lighting circuit. Understand how junction boxes are used to connect and distribute electricity for lighting fixtures in your home or building.

0 · sheet metal rib design guidelines

1 · sheet metal fabrication design guide

2 · sheet metal design guidelines pdf

3 · sheet metal design calculations pdf

4 · sheet metal bracket design guidelines

5 · sheet metal basic design guidelines

6 · existing designs for brackets

7 · basics of sheet metal design

Trailer Wiring & Electrical at Tractor Supply Co. Buy online, free in-store pickup. Shop today!

In this guide, we share some background on the processes we use to manufacture custom sheet metal brackets, explore different bracket types, . When it comes to sheet-metal brackets, there are several standard styles and shapes. Each sheet metal bracket style serves a specific requirement for mounting a component, or being compatible with a particular surface shape. Sheet metal fabrication design guide with tips and best practices on designing sheet metal parts for processing via laser cutting and precision CNC bending.Sheet metal design guidelines are followed for sheet metal enclosure and part design to ensure the first time right product and reduce cost.

So you decided to design your own sheet metal part. Use the following simple guidelines to formulate and design the type of sheet metal bracket you will need to successfully meet your requirements. The starting point is determining what .Creating a hem in sheet metal requires special tooling and machinery, often involving press brakes or other sheet metal forming equipment. Proper design and execution of hems is essential to ensure they don't split or deform during .

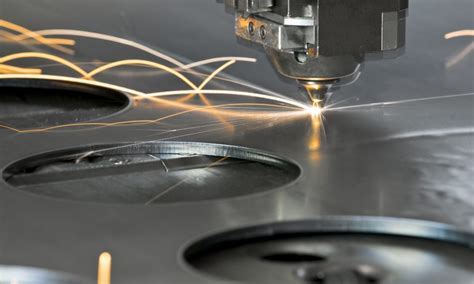

Sheet metal fabrication is the process of forming parts from a metal sheet by punching, cutting, stamping, and bending. 3D CAD files are converted into machine code, which controls a .

Key factors to consider when designing sheet metal brackets. Designing sheet metal brackets requires careful planning and understanding of the functional requirements. Here are some crucial factors to consider: 1. . Making sheet metal brackets may seem like a daunting task but it doesn't have to be. With the right techniques and tips, you can turn your ideas into reality. In this comprehensive guide, we'll walk you through the steps . In this guide, we share some background on the processes we use to manufacture custom sheet metal brackets, explore different bracket types, and share tips to help you design the ideal custom brackets for your applications. When it comes to sheet-metal brackets, there are several standard styles and shapes. Each sheet metal bracket style serves a specific requirement for mounting a component, or being compatible with a particular surface shape.

But how do you go about creating a sheet metal bracket? 3ERP has years of expertise in sheet metal prototyping, and this guide explains the basics of sheet metal brackets, including common bracket types, bracket design tips, and the best sheet metal bracket materials. Sheet metal fabrication design guide with tips and best practices on designing sheet metal parts for processing via laser cutting and precision CNC bending.Sheet metal design guidelines are followed for sheet metal enclosure and part design to ensure the first time right product and reduce cost.So you decided to design your own sheet metal part. Use the following simple guidelines to formulate and design the type of sheet metal bracket you will need to successfully meet your requirements. The starting point is determining what loading .

Creating a hem in sheet metal requires special tooling and machinery, often involving press brakes or other sheet metal forming equipment. Proper design and execution of hems is essential to ensure they don't split or deform during the bending process.

Sheet metal fabrication is the process of forming parts from a metal sheet by punching, cutting, stamping, and bending. 3D CAD files are converted into machine code, which controls a machine to precisely cut a flat pattern, which can be formed . Key factors to consider when designing sheet metal brackets. Designing sheet metal brackets requires careful planning and understanding of the functional requirements. Here are some crucial factors to consider: 1. Instructions . Making sheet metal brackets may seem like a daunting task but it doesn't have to be. With the right techniques and tips, you can turn your ideas into reality. In this comprehensive guide, we'll walk you through the steps necessary to make your own custom sheet metal brackets. In this guide, we share some background on the processes we use to manufacture custom sheet metal brackets, explore different bracket types, and share tips to help you design the ideal custom brackets for your applications.

When it comes to sheet-metal brackets, there are several standard styles and shapes. Each sheet metal bracket style serves a specific requirement for mounting a component, or being compatible with a particular surface shape. But how do you go about creating a sheet metal bracket? 3ERP has years of expertise in sheet metal prototyping, and this guide explains the basics of sheet metal brackets, including common bracket types, bracket design tips, and the best sheet metal bracket materials. Sheet metal fabrication design guide with tips and best practices on designing sheet metal parts for processing via laser cutting and precision CNC bending.Sheet metal design guidelines are followed for sheet metal enclosure and part design to ensure the first time right product and reduce cost.

So you decided to design your own sheet metal part. Use the following simple guidelines to formulate and design the type of sheet metal bracket you will need to successfully meet your requirements. The starting point is determining what loading .Creating a hem in sheet metal requires special tooling and machinery, often involving press brakes or other sheet metal forming equipment. Proper design and execution of hems is essential to ensure they don't split or deform during the bending process.

Sheet metal fabrication is the process of forming parts from a metal sheet by punching, cutting, stamping, and bending. 3D CAD files are converted into machine code, which controls a machine to precisely cut a flat pattern, which can be formed .

Key factors to consider when designing sheet metal brackets. Designing sheet metal brackets requires careful planning and understanding of the functional requirements. Here are some crucial factors to consider: 1. Instructions .

metal bird houses wholesale

sheet metal rib design guidelines

sheet metal fabrication design guide

Learn how to install an electrical outlet from a junction box. In this video tutorial, I will show you how to wire an electrical outlet and how to wire the e.

design of sheet metal brackets|sheet metal design guidelines pdf