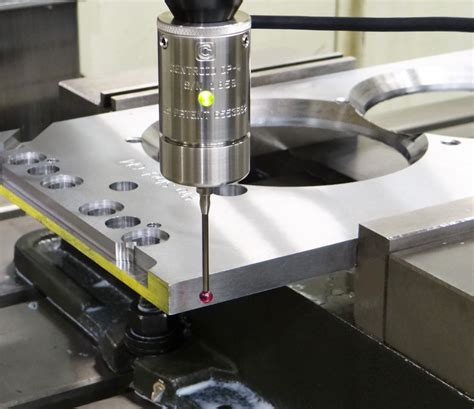

add probing to a cnc milling machine The machine tool probing systems can be used on CNC machining centers, lathes and more equipment to identify and set up parts, monitor workpiece surface condition, measure features, and verify finished . Then, weld the sheet metal pieces to create a metal box. The skills you’ll learn when welding this metal shop box will come in handy when you start working on bigger welding projects. It’s also an excellent project if you’re .

0 · pros of cnc machine probing

1 · probing techniques in cnc

2 · mechanical tool probing

3 · machine tool probing systems

4 · cnc probe tool

5 · cnc probe programming

6 · cnc machine probing problems

7 · cnc machine probing

Go even further to increase natural light in your bathroom by adding a freestanding bath finished with a reflective metallic surface and pair with white walls and white marble floor to help the light bounce around the room.

Precise workpiece and tool measurement on a CNC machine helps to achieve accurate and consistent machining results, enhancing productivity, and minimising the risk of costly errors. Machine tool probes for workpiece setting .Automate your setup process with the Haas Wireless Intuitive Probing System (WIPS). WIPS allows you to quickly and easily define work offset coordinates, set tool length offsets, and perform in-process inspection, for both part inspection and tool breakage detection.Set up your Haas mill up to 5 times faster using the Haas Wireless Intuitive Probing System (WIPS). WIPS is a complete probing package that includes the spindle probe, tool setting .The DATRON CNC Probe for surface mapping detects and compensates for irregular material surfaces. For milling or engraving on rounded surfaces, a probe like DATRON’s Z-Correction Probe is required and in many cases, a rotary .

The machine tool probing systems can be used on CNC machining centers, lathes and more equipment to identify and set up parts, monitor workpiece surface condition, measure features, and verify finished .

CIMCO Probing automatically generates and inserts the machine-independant G-code directly in your NC program. Use CIMCO Probing to improve the quality of parts, increase productivity . If you want to streamline production and be competitive in the industry, you will need far more than a standard three-axis CNC mill or two-axis CNC lathe and a few measuring tools. Choosing the Correct Gage Type for .

Probing in CNC machines ensures that all parts are correctly machined by enabling the controller to compensate for misaligned parts; It reduces off-machine inspection requirements; Probing reduces scrap associated with differences in the sizes of the stock billets; Challenges and Solutions in Probing. The challenges of probing in CNC machining are:Precise workpiece and tool measurement on a CNC machine helps to achieve accurate and consistent machining results, enhancing productivity, and minimising the risk of costly errors. Machine tool probes for workpiece setting and inspection gather data on the shape, size, and position of a workpiece.

pros of cnc machine probing

Automate your setup process with the Haas Wireless Intuitive Probing System (WIPS). WIPS allows you to quickly and easily define work offset coordinates, set tool length offsets, and perform in-process inspection, for both part inspection and tool breakage detection.Set up your Haas mill up to 5 times faster using the Haas Wireless Intuitive Probing System (WIPS). WIPS is a complete probing package that includes the spindle probe, tool setting probe, and optical machine interface, along with powerful software that guides the operator through the job setup process with intuitive, easy-to-use templates.The DATRON CNC Probe for surface mapping detects and compensates for irregular material surfaces. For milling or engraving on rounded surfaces, a probe like DATRON’s Z-Correction Probe is required and in many cases, a rotary axis is also necessary.

The machine tool probing systems can be used on CNC machining centers, lathes and more equipment to identify and set up parts, monitor workpiece surface condition, measure features, and verify finished part dimensions. The probe of machine tool is the best choice of machining complex curved surface.

CIMCO Probing automatically generates and inserts the machine-independant G-code directly in your NC program. Use CIMCO Probing to improve the quality of parts, increase productivity and reduce setup time and manual processes.

If you want to streamline production and be competitive in the industry, you will need far more than a standard three-axis CNC mill or two-axis CNC lathe and a few measuring tools. Choosing the Correct Gage Type for Groove InspectionThis document focuses on the main applications for probing on machine tools. It contains an introduction to the use of probing for each application, plus guidance on the selection of the most appropriate system and technical information about each probe.Advanced Probing. Your machine tool probe likely came with software that allows you to run many standard probing cycles such as X, Y, and Z surface measurements, bore measurements, and web/pocket measurements. Probing in CNC machines ensures that all parts are correctly machined by enabling the controller to compensate for misaligned parts; It reduces off-machine inspection requirements; Probing reduces scrap associated with differences in the sizes of the stock billets; Challenges and Solutions in Probing. The challenges of probing in CNC machining are:

Precise workpiece and tool measurement on a CNC machine helps to achieve accurate and consistent machining results, enhancing productivity, and minimising the risk of costly errors. Machine tool probes for workpiece setting and inspection gather data on the shape, size, and position of a workpiece.Automate your setup process with the Haas Wireless Intuitive Probing System (WIPS). WIPS allows you to quickly and easily define work offset coordinates, set tool length offsets, and perform in-process inspection, for both part inspection and tool breakage detection.Set up your Haas mill up to 5 times faster using the Haas Wireless Intuitive Probing System (WIPS). WIPS is a complete probing package that includes the spindle probe, tool setting probe, and optical machine interface, along with powerful software that guides the operator through the job setup process with intuitive, easy-to-use templates.The DATRON CNC Probe for surface mapping detects and compensates for irregular material surfaces. For milling or engraving on rounded surfaces, a probe like DATRON’s Z-Correction Probe is required and in many cases, a rotary axis is also necessary.

The machine tool probing systems can be used on CNC machining centers, lathes and more equipment to identify and set up parts, monitor workpiece surface condition, measure features, and verify finished part dimensions. The probe of machine tool is the best choice of machining complex curved surface.CIMCO Probing automatically generates and inserts the machine-independant G-code directly in your NC program. Use CIMCO Probing to improve the quality of parts, increase productivity and reduce setup time and manual processes. If you want to streamline production and be competitive in the industry, you will need far more than a standard three-axis CNC mill or two-axis CNC lathe and a few measuring tools. Choosing the Correct Gage Type for Groove InspectionThis document focuses on the main applications for probing on machine tools. It contains an introduction to the use of probing for each application, plus guidance on the selection of the most appropriate system and technical information about each probe.

chanel pink silver metallic tweed fabric knit bag

century art steel file cabinets keys

Transolid combines an unprecedented 16-gauge stainless steel laundry/utility sink with the accessories to make your space work as hard as you do. The handmade stainless steel sink features a modern and easy-to-clean 10mm radius, pre .

add probing to a cnc milling machine|cnc machine probing