using cnc machine How CNC Machining Works. CNC machining is the process of using computer software to guide machines, taking a virtual design and turning it into a tangible, three-dimensional product.This process is a form of subtractive . To find the correct drill bit size, check the screw size, test the fit, consider material type, use pilot holes, and match the drill bit to the screw head type for a polished finish. .

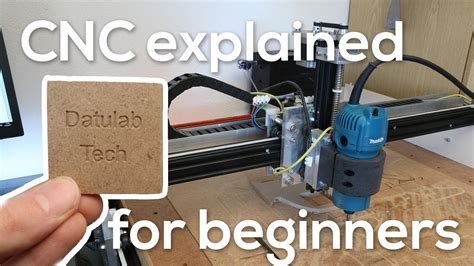

0 · learning cnc machine for beginners

1 · cnc tutorial for beginners

2 · cnc machines for dummies

3 · cnc machine step by

4 · cnc machine process step by

5 · cnc for dummies book

6 · basic knowledge of cnc machine

7 · basic cnc for beginners

To figure out the size of air compressor you need, first determine the CFM (cubic feet per minute) rating of your machine. This can be found in the owner’s manual or on the machine itself. Once you know the CFM rating, multiply it by 4 to get the minimum air .

In this video, I'll cover all the CNC basics that you must know before being able to run the machine. This includes CAD, CAM, Feeds and Speeds, Toolpaths, G-code, and setting up the machine. How CNC Machining Works. CNC machining is the process of using computer software to guide machines, taking a virtual design and turning it into a tangible, three-dimensional product.This process is a form of subtractive .

What is CNC: CNC stands for computer numerical control, which is a process of using computer software to control the movement and operation of machines that can cut, carve, or engrave materials.; Types of CNC machines: . Watch Next - 3D Printer Basics: https://youtu.be/RgECxaxUIb0CNC Routers for Hobbyists can be intimidating! In this video, I'll cover all the CNC basics that . 1. Set-Up Person How Set-Up Person uses CNC Machines: Manage daily scheduling of production workload to be setup and run on machinery. Machine large parts for the mining, aerospace, and power industries.

Once you’ve found the CNC router that’s right for you, consider which CNC software to use. Some CNC machines come with built-in routing software, but if yours doesn’t, check out these options: Vectric Vcarve Pro; Easel; Vectric Aspire; Mach4; PlanetCNC; To get used to using your CNC machine, there are a ton of free DXF files available . The Maker Made M2 is the new and upgraded version of the original Maslow CNC. Modernized and upgraded for 2023, the Maker Made M2 still offers the fantastic 4 x 8 foot cutting range, as well as excellent 1mm accuracy, as well as a laser engraver upgrade kit.. For the extra money, you get an all-metal Z-axis, 40-inch cutting speed per minute, and built-in .

CNC machines are modern subtractive manufacturing equipment, which automatically control the tool path and movement for material removal. You can find different types of CNC machines in industrial factories and the CNC Machine Shop, each with specific manufacturing purposes.However, all of them are used to craft the blank work material into the .

As a result, using CNC machines for home décor is a popular idea and offers a host of CNC project ideas to sell, and even a great way to spruce up your own house too. Home and Business Signs. Download Example: Etsy; Designer: Casey Reames; Price: .50 CNC machining for cabinetry is an obvious extension of what CNC machines can accomplish. Cabinet manufacturing is one of the most common applications for CNC machines, whether used to create customized or more standard pieces. CNC drilling machines are also widely used in cabinetry and furniture to create precise parts.

learning cnc machine for beginners

stainless steel with white cabinets

In this video I will walk you through some very simple steps to make your first cuts on a CNC machine. In February I got the Axiom AR8 Pro from my good frien.Keep the machine clean: Regularly remove chips, dust, and debris from all areas of the machine using compressed air or vacuum cleaners. Lubricate moving parts: Apply lubricants as the manufacturer recommends to reduce friction and wear on moving components. Check coolant levels: Ensure an adequate supply of coolant during machining operations. Inspect and .

we have books with tips and tricks, tutorials, and design for cnc: https://www.makershed.com/products/make-cnc-epack-pdfs Machines, along with CAM software, play a central role in automating vast swathes of the manufacturing industry. Despite this benefit, these machines present an element of risk and danger. CNC machines, for example, move at lightning-fast speeds – sometimes rotating at speeds of up to 300,000 rpm, as is the case with some micro-machining systems. . Behind .CNC Machining is a subtractive manufacturing technology, where material is removed from a solid block, or workpiece, using various CNC machining equipment such as milling machines, lathes, and grinders. This process is known for its high precision and versatility in creating a wide range of materials, including metal, plastic, wood, foam, and .

CNC machines have revolutionized the manufacturing industry, providing precise and efficient solutions for various tasks. To fully grasp the capabilities of these machines, it is essential to understand their basic components, the different . Engraving the brand name and logo can also be done with the help of a CNC machine. Furniture. Furniture making uses CNC machines for many materials such as wood, glass, metal, plastic, and even upholstery. The range .

stainless steel wallmount enclosures

The key elements of a CNC machine are described as the input device, machine control unit, machine tool, driving system, feedback devices, and display unit. The document also covers the basic programming and operation . To use a CNC machine, you will need to have the proper software installed on your computer. This software will allow you to create the designs that you want to cut out with your CNC machine. There are many different types of software available, so you will need to choose the one that is right for your specific needs. .How a CNC Machine Works. In CNC machining, computer code controls the movement of machine tools and equipment. The code tells the machine to move in specific directions and at specific speeds. It also gives instructions for cutting and shaping material. Automating these functions enables greater levels of precision, complexity, and production .The history of CNC (Computer Numerical Control) technology dates back to the mid-20th century. In the late 1940s and early 1950s, researchers and engineers began exploring ways to automate machine tool operations using electronic controls. Early efforts involved analog computers and punch-card systems to control machine movements.

10 Industries that Use CNC Machines: 1. Aerospace Industry: In the aerospace industry, CNC machines are crucial for making parts you depend on when flying. 5-axis CNC mills and CNC lathes are commonly used to craft precise parts from tough materials like titanium and aluminum. These machines produce engine parts that help planes fly and landing . A CNC machine, or computer numerical control machine, is a piece of equipment that manufactures parts according to preprogrammed computer directions. The techniques you can apply in CNC machines are even more varied than the types of machines you can use, but this blog will cover only subtractive machining centers like mills, lathes, routers, etc.

It’s just like the plan we started with, thanks to the CNC machine. Now that you know how CNC machines work, let’s talk about the good things and not-so-good things about them. 5 Advantages of CNC Machines: 1. Precision & Accuracy: CNC machines are super good at making things exactly the way we want. Computerized numerical control (CNC) machines are used across various industries, ranging from aerospace to medical. Operating a commercial CNC machine requires specialized training and distinct traits, such as a keen eye for detail, tech-savviness, creativity and problem-solving skills.. Because CNC machines use highly complex technology, they’re often . Key Components of a CNC Machine. To effectively use a CNC machine, it’s crucial to familiarize yourself with its key components. Here are the parts you’ll interact with the most: Control Panel: This is the heart of the CNC machine where you input instructions, monitor the machine’s progress, and control its operations. .

Furthermore, Arduino can control various CNC machines, ranging from 3D printers to laser cutters. That said, Arduino is the best controller if you want to build a CNC machine. Let's now get started on how to build a simple CNC machine using Arduino. What You Will Need. To create a CNC machine with Arduino, you will need:-An Arduino microcontrollerYou can engrave names, initials, or even intricate designs onto these essential table accessories using a CNC machine. Not only will they protect your surfaces from stains and spills, but they will also add an extra touch of elegance to your dining experience. SYIL Machine Tools' precision CNC machines ensure precise engraving on various .

cnc tutorial for beginners

stainless steel waterproof enclosure

$19.99

using cnc machine|cnc machine step by